|

We are often asked how well our Conical

Merge Collectors perform on the dyno against traditional,

and much more expensive, welded merge collectors. Many of

our long-time customers have done extensive dyno testing

that showed they performed very well but we didn’t

have hard data to share. Now we do!

We were approached by a long-time customer

that planned to use a set of our collectors for a header

they were designing for a new customer. Their customer wanted

to use a welded merge and wasn’t too concerned about

cost just plain performance. But isn’t that what we

all say until they get the bill? We were requested to prepare

a collector kit that would be comparable to the welded merge

collectors he was given in order to conduct a direct dyno

comparison. His customer just couldn’t believe that

our $50 collector would perform as well as a $350 collector!

In fairness, there are some differences in the collectors

that should be disclosed. First, their collector was finished

and ready to bolt on. Ours was a kit that required some assembly.

It takes about two hours to assemble and weld a pair of collectors

to the header. Slip-on collectors do take slightly longer to

build. And you will need to have some basic fabrication tools

such as a TIG or MIG welder, a hand grinder and a saw, preferably

a metal cutting bandsaw.

How to build a Megs

Conical Merge Collector, click here >> Collector

Assembly Guide

The two different collectors would have to be as similar as

possible in dimensions for the results to be comparable. If

the collectors differed in this regard it would call into question

the results and defeat the purpose of the test. In addition,

the unique nature of the test engine also required some slight

customization of each collector.

Neither we nor the builder of the welded merge collectors

set the collector specifications; these were all set by the

customer. This individual has been building high-performance

and race exhausts for many years. On this project he was working

with a major aftermarket automotive company.

The test engine is a 482 cubic inch big

block Ford V8 with a 4.25” stroke and 4.25” bore. In earlier tests

it generated around 550 horsepower. The base collector they

selected would use 2” primary inlets and a 3.50” diameter

outlet. This would be matched up to a 3.50” x 4.50” x

8.25” length (7 degree) transition cone.

The welded merge collector that our competitor supplied was

a very beautiful part. The welding was top-notch and even the

inside of the collector had a fantastic polished finish! It

was going to be tough to compete against something like this,

but we had to know once and for all how we stacked up!

We supplied our customer a collector kit

that included (2) 2” 4-into-1 304 Stainless Steel collectors,

(8) matching bullet vanes and the fixture tool to assemble

the merge bullets. Also included were a set of transition

cones as previously described. Our customer then assembled

everything, adding additional tubing to fabricate it as a

slip-fit collector. Similar to the welded merge collector,

we generally recommend blending and polishing the bullet

assembly for optimum performance. However in this case, they

were left unfinished.

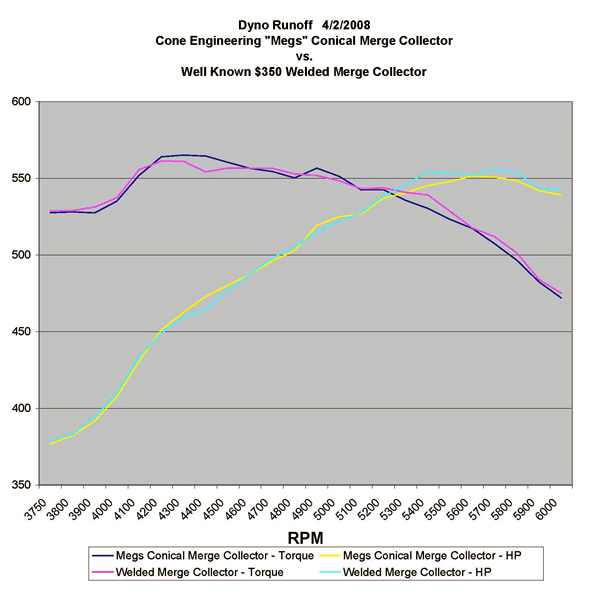

Now came the moment of truth, back-to-back

dyno pull using the same set of headers….

As you can see from the chart above, the

results were amazingly similar! At certain RPM’s there

are differences. Generally, the Megs collector produced more

HP and Torque up to about 5200 RPM. The competitor pulled

slightly more from 5200 to 6000. When you consider the RPM

that most street-driven vehicles operate at, the results

were astounding! Compare the prices and it could be hard

to justify spending several hundred dollars for gains seen

only in the upper reaches of usability! Now if you are building

a full-bore money-is-no-object racecar, you might be able

to make an argument. And if he had just polished those bullets…

|